|

The Formax FD 300 Office Desktop Folder provides an economical solution for low-volume folding projects.

This compact folder processes 11" and 14" paper at speeds up to 7,400 sheets per hour, and is pre-marked for four popular folds: C, Z, Half and Double Parallel. User-friendly features include an LCD control panel with 3-digit resettable counter, AutoBatch for processing sets of documents, and an output conveyor with easily-adjustable stacker wheels for neat sequential stacking of folded pieces. Clearly marked fold settings and out-of-the-box operation make this folder ideal for churches, schools and small offices that demand quick and easy set-up with minimal adjustment. FD 300 Product Spec Sheet |

|

|

|

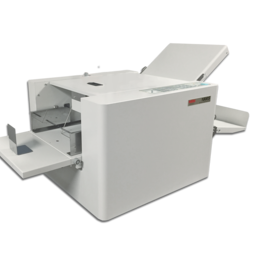

The Formax FD 314 Office Desktop Folder provides an economical solution for low-volume folding projects. It combines a compact footprint with push-button controls, so it's simple to use, right out of the box! Fold plates are clearly marked for four common folds - letter, zig-zag, half and double parallel - and can be easily adjusted for custom folds. With a three-tire drop-in feed system, it processes 11” and 14” paper at speeds up to 7,700 sheets per hour, and offers a hopper capacity of up to 250 sheets.

The LCD control panel includes a resettable 3-digit counter, and AutoBatch for processing a set number of sheets with a pause between sets. The built-in output conveyor features adjustable stacker wheels for neat, sequential stacking of folded pieces. User-friendly fold settings and straighforward operation make this folder ideal for churches, schools, and offices that demand quick and easy set-up with minimal adjustment. FD 314 Product Spec Sheet |

|

The MBM 208J folder is a 3 roller friction feed system. Easy set-up for standard and custom folds. Control panel includes LED 4 digit counter with addition and subtraction functions. Test button folds 2 sheets for inspection. Extended exit tray for neat stacking of folded sheets. Automatic conveyor ensures smooth ejection of folded paper. Single sheet feeding automatically maintained for different weights of paper. Auxiliary paper guide for cross folding. Load and unload paper from same side. Display alert and audible signal in case of incorrect operation. Skew and micro-adjustment dials. Quick-release roller system for easy maintenance.

208J Product Spec Sheet |

|

|

|

The FD 324 Document Folder offers an unmatched level of performance and affordability. This rugged, compact unit processes up to 8,600 sheets per hour in 11”, 14” and 17” paper sizes. Removable top and bottom fold plates provide for quick and easy set-up. Fold plates are clearly marked for four common fold settings: Letter, Zig-Zag, Double Parallel, and Half. Quick release fold stops and fine tune adjustment knobs ensure crisp, accurate folds every time.

Designed with ease of operation in mind, it utilizes a drop-in feed system, eliminating the need to fan paper. Simply square the paper stack and load it into the feed tray. |

The LCD control panel features a 3-digit resettable counter and AutoBatch, which allows users to process a specific number of sheets with a pause between sets, for easy unloading. Its output conveyor includes easily adjustable stacker wheels for neat, sequential stacking of folded pieces

As with all Formax folders, the FD 324 is constructed with a heavy-duty steel frame and molded, high-impact side covers for durability. The three-tire friction feed accurately pulls paper info the folder, while the skew adjustment allows for moving the feed table left or right, to produce crisp, accurate folds.

Clearly-marked fold settings and simple out-of-the-box operation make it the perfect addition to schools, churches, and offices looking for easy setup and minimal adjustments.

FD 324 Product Spec Sheet

As with all Formax folders, the FD 324 is constructed with a heavy-duty steel frame and molded, high-impact side covers for durability. The three-tire friction feed accurately pulls paper info the folder, while the skew adjustment allows for moving the feed table left or right, to produce crisp, accurate folds.

Clearly-marked fold settings and simple out-of-the-box operation make it the perfect addition to schools, churches, and offices looking for easy setup and minimal adjustments.

FD 324 Product Spec Sheet

|

The MBM 408A Folder is an Automatic 3 roller friction feed system. Pre-programmed with 36 standard folds. Stores 12 custom folds in memory. Color LCD touch screen control panel includes 4 digit addition / subtraction digital counter. Test button folds 2 sheets for inspection. Automatically senses and displays paper size. Extended exit tray for neat stacking of folded sheets. Automatic conveyor ensures smooth ejection of folded paper. Single sheet feeding automatically maintained for different weights of paper. Auxiliary paper guide for cross folding. Load and unload paper from same side. Display alert and audible signal in case of incorrect operation. Skew and micro-adjustment dials. Fully enclosed fold tables for quiet operation. Quick-release roller system for easy maintenance. Optional scoring, micro-perforating, and slitting units.

408A Product Spec Sheet |

|

|

|

The FD 346 Document Folder is a fast, dependable and easy-to-use solution for virtually all folding applications. Its color touchscreen control panel features internationally-recognized symbols in place of text, making it easy for anyone to use. Six popular folds are clearly marked on the fold plates for quick set-up and operation, simply slide the fold stop to the desired fold and go. Additional adjustments can be made with the fine tuning knobs at the end of each fold plate for precision folding. No need to stand and watch over this folder: operators can load up to 500 sheets in the hopper, select their fold, press start and walk away to attend to other important tasks. |

The FD 346 will fold the 500 sheets in no time at all and hold the folded pieces on its patented telescoping conveyor system until they are retrieved.

The optional Multi-Sheet Feeder allows up to 4 stapled or unstapled sheets to be folded at one time through a dedicated feed system with its own side guides and skew adjustment system.

The FD 346 is capable of processing paper up to 18” in length and up to 12” in width giving it the flexibility to handle a variety of paper sizes. With its customizable jobs, operators can fold in virtually any configuration that requires only two folds. Cross folding adds to the FD 346’s flexibility allowing for additional folds in a second pass.

The innovative touchscreen, simple set-up and operation make the FD 346 an ideal solution for any church, school or small business that is cost conscious but requires the easy operation, versatility and dependability of a more expensive folder.

FD 346 Product Spec Sheet

|

The MBM 508A Automatic 3 roller friction feed system. Pre-programmed with 36 standard folds. Stores 24 custom folds in memory. Automatic feed table elevation. Features paper feed pressure and separator pressure adjustment. Color LCD touch screen control panel includes 4 digit addition and subtraction digital counter. Test button folds 2 sheets for inspection. Automatically recognizes and displays paper size. Extended exit tray for neat stacking of folded sheets. Automatic conveyor and self-setting exit rollers ensure smooth ejection of folded paper. Single sheet feeding automatically maintained for different weights of paper. Auxiliary paper guide for cross folding. Load and unload paper from same side. Display alert and audible signal in case of incorrect operation. Skew and micro-adjustment dials. Fully enclosed fold tables for quiet operation. Quick-release roller system for easy maintenance. Optional scoring, micro-perforating, and slitting units.

508A Product Spec Sheet |

|

|

|

The FD 386 Automatic Touchscreen Document Folder offers any business, church, school or print-for-pay center quick, easy set-up, and the versatility to complete a variety of fold jobs in minutes. Jobs are completed exceptionally fast with the FD 386, folding up to 17,000 pieces per hour! Fully automated fold plates provide one touch set-up of the 18 pre-programmed fold settings or for choosing one of the 27 custom folds that can be stored into memory. In addition, the full-color touchscreen control panel makes the FD 386 extremely easy to use with a step-by-step user interface that is second to none.

Operators can load up to 500 sheets in the hopper, select their fold, press start and walk away to attend to other important tasks. The FD 386 will fold the 500 sheets in as fast as 2 minutes and hold the folded pieces on its patented Telescoping Conveyor System. |

The patented Multi-Sheet Feeder is an optional feature that allows up to 4 stapled or unstapled sheets to be folded at one time through the dedicated feed system with its own side guides and skew adjustment.

The large full-color touchscreen control panel allows for untrained operators to walk up and start folding with little to no instruction. The FD 386 advanced software allows for all standard fold types and paper sizes to be customized to meet your particular needs.

The FD 386 can also be combined with the optional Formax V-Stack36i Vertical Stacker, which stacks up to 22” of folded documents, making them easier to unload for further processing.

When it comes to paper folding, no one does it faster or with higher quality than the Formax FD 386!

FD 386 Product Spec Sheet

The large full-color touchscreen control panel allows for untrained operators to walk up and start folding with little to no instruction. The FD 386 advanced software allows for all standard fold types and paper sizes to be customized to meet your particular needs.

The FD 386 can also be combined with the optional Formax V-Stack36i Vertical Stacker, which stacks up to 22” of folded documents, making them easier to unload for further processing.

When it comes to paper folding, no one does it faster or with higher quality than the Formax FD 386!

FD 386 Product Spec Sheet

|

The FD 38Xi Fully Automatic Touchscreen Document Folder is the ideal solution for any business, church, school or print-for-pay center that demands quick and easy set-up. The FD 38Xi features a full-color touchscreen control panel making it extremely easy to use and provides a user interface that is second to none. Fully automated fold plates and AutoStackTM Stacker Wheels provide one touch set-up of the 18 pre-programmed fold settings or for choosing one of the 36 custom folds that can be stored into memory.

The FD 38Xi is fast, folding up to 17,000 pieces per hour! Operators can load up to 500 sheets in the hopper, select their fold, press start and walk away to attend to other important tasks. The FD 38Xi will fold the 500 sheets in as little as 2 minutes and hold the folded pieces on its patented Telescoping Conveyor System. |

|

The dedicated Multi-Sheet Feeder folds up to 4 stapled or unstapled sheets at one time, with the ability to choose standard or custom folds in letter and legal paper sizes.

The large full color touchscreen control panel allows for untrained operators to walk up and start folding with little to no instruction. The FD 38Xi advanced software allows for all standard fold types and paper sizes to be customized to meet your particular needs.

The FD 38Xi can be paired with the optional V-Stack36i Vertical Stacker, which stacks up to 22” of folded documents, making them easier to unload for further processing.

When it comes to paper folding, no one does it faster or with higher quality than the Formax FD 38Xi!

FD 38Xi Product Spec Sheet

The large full color touchscreen control panel allows for untrained operators to walk up and start folding with little to no instruction. The FD 38Xi advanced software allows for all standard fold types and paper sizes to be customized to meet your particular needs.

The FD 38Xi can be paired with the optional V-Stack36i Vertical Stacker, which stacks up to 22” of folded documents, making them easier to unload for further processing.

When it comes to paper folding, no one does it faster or with higher quality than the Formax FD 38Xi!

FD 38Xi Product Spec Sheet

The 1800S by MBM is the new and improved model of the 1500S. The ultrasonic double feed sensor is new to this model. The 1500S could not detect double feeds on black or transparent sheets, but the new 1800S detects double feeds on any white, printed, transparent, black or mixture of colored sheets. Also new to the 1800S is the removable folding roller for easy maintenance, the adjustable folding roller pressure, and a spring loaded feed angle adjustment dial. The machine top cover opens and closes in two easy steps and the operator can now reach the air adjustment knob without disruption when the top cover is open. New “silver top” metal sheet for smoother paper run and better electric conductivity. Top feed, adjustable air suction feed system, suitable for digitally printed and coated stocks. Pre-programmed with 6 standard folds. Stores 30 custom folds in memory. One-touch memory keys for custom folds. Non-standard paper sizes can be stored in memory. Control panel includes LED 4 digit counter with batch and total functions. Test button folds 2 sheets for inspection. Extended exit tray for neat stacking of folded sheets. Automatic feed table ensures optimum feed pressure. Automatic conveyor belt and self-setting exit rollers ensure smooth ejection of folded paper. Single sheet feeding automatically maintained for different weights of paper. Display alert and audible signal in case of incorrect operation. Skew and micro-adjustment dials. All-metal construction. Optional micro-perforator, and scorer.

1800S Product Spec Sheet

1800S Product Spec Sheet

|

The FD 3300 Air-Suction Document Folder offers high performance folding in a compact tabletop unit, ideal for digitally printed documents on heavy and coated stock. The air-suction feed technology reduces static electricity and minimizes feed marks common in traditional friction feed systems. The FD 3300 utilizes internal fans to produce air and suction for quiet operation in a smaller footprint. The feeding system also includes a side air system for enhanced feeding of heavier stocks and larger sheets of paper.

With a speed of up to 18,600 sheets per hour, and a feed tray capacity of up to 625 sheets, the FD 3300 quickly powers through a range of applications, all at the touch of a button, while Optical |

|

and Ultrasonic Double Feed Detection ensures document integrity. To accommodate a variety of paper weights and sizes, fan speed and air flow can be adjusted independently using the interactive control panel and external adjustment knobs.

User-friendly features include automatic paper size detection and fold plate settings, 4.3” color touch screen LCD control panel, six programmed fold settings, and the ability to store up to 30 custom folds. The FD 3300 includes a cross folding guide, a four-digit counter with batch counting capability, four fold rollers for accuracy, and a variety of document security features.

Fully automated and insulated for quiet operation, the FD 3300 is ideal for on demand printing in the office environment.

FD 3300 Spec Sheet

352F

352F

The MBM 352F features Dual roller friction feed system accepts a wide variety of stocks. Adjusts in seconds for standard and custom folds. Variable speed control. Powered exit conveyor. Sheet separation from top of fanned stack. Polyurethane foam rollers eliminate the need for fold roller pressure settings. Heavy-duty, non-flexing side frames. Needle bearings for high speed production. Optional extended delivery system, crossfold for right-angle folding, and slitting, scoring, and perforating attachments. UL and C UL approved.

Dimensions (D x W x H), inches: 22 1/4 x 41 3/4 x 14 1/2

Shipping weight, pounds: 105

352F

Speed, sheets per hour 22,000* Paper size, inches 2 x 2 3/4 to 14 x 21 1/4 Paper weight, pounds 13 to 110* Sheet capacity 300*

Electrical requirements 115 V, 60 Hz

352F Spec Sheet

Dimensions (D x W x H), inches: 22 1/4 x 41 3/4 x 14 1/2

Shipping weight, pounds: 105

352F

Speed, sheets per hour 22,000* Paper size, inches 2 x 2 3/4 to 14 x 21 1/4 Paper weight, pounds 13 to 110* Sheet capacity 300*

Electrical requirements 115 V, 60 Hz

352F Spec Sheet

Air suction feed system, suitable for coated stocks. Adjusts in seconds for standard and custom folds. Variable speed control. Powered exit conveyor. Bottom-feed, top-loading design for continuous reloading and dependable sheet separation. Polyurethane foam rollers eliminate the need for fold roller pressure settings. Turbine blower fully enclosed for quiet operation. 2 fold plates. Heavy-duty, non-flexing side frames. Needle bearings for high speed production. Mounted on casters. Optional extended delivery system, crossfold for right-angle folding, and slitting, scoring, and perforating attachments. UL and C UL approved.

Dimensions (D x W x H), inches: 22 1/4 x 51 1/4 x 43 1/2

Shipping weight, pounds: 312 lbs.

352S

Speed, sheets per hour 30,000* Paper size, inches 3 3/8 x 4 3/4 to 12 5/8 x 17 3/4 Paper weight, pounds 13 to 110* Sheet capacity 450* Electrical requirements 115 V, 60 Hz

352S Product Spec Sheet

Dimensions (D x W x H), inches: 22 1/4 x 51 1/4 x 43 1/2

Shipping weight, pounds: 312 lbs.

352S

Speed, sheets per hour 30,000* Paper size, inches 3 3/8 x 4 3/4 to 12 5/8 x 17 3/4 Paper weight, pounds 13 to 110* Sheet capacity 450* Electrical requirements 115 V, 60 Hz

352S Product Spec Sheet

|

|

The ATLAS Air-Feed Document Folder combines high-volume output with user-friendly features in a rugged, small footprint. With variable speed control, it can process up to 27,000 sheets per hour. Six standard folds are pre-set in letter, legal and ledger paper sizes, making it easy for operators to setup and run jobs. Fully-enclosed fold plates feature dials to select fold plate position and LED displays accurate to 0.1mm. The fold rollers are made of a durable composite material designed to easily grip high-gloss paper, and are housed in a single patented pull-out cassette.

The powerful air suction feed table handles a wide variety of coated or non-coated stock, up to 25.5” in length, and aligns the sheets prior to folding. It also features a suction chamber to control curled or statically charged paper. |

Standard features include a modular perforator/scorer which can also be used as a roller bypass, allowing cover stock to be folded and output flat. The belt-driven outfeed stacker is located on the same side as the infeed, allowing operators to easily operate the Atlas from a single position. Double document and jam detection, batch counting, anti-static brushes, skew and micro adjustments complete the user-friendly package.

The Atlas Air-Feed Folder is ideal for those with big folding jobs and limited space.

Atlas Product Spec Sheet

The Atlas Air-Feed Folder is ideal for those with big folding jobs and limited space.

Atlas Product Spec Sheet

|

The ATLAS-AS Air-Feed Document Folder combines high-volume output with user-friendly features in a rugged, small footprint. With variable speed control, it can process up to 27,500 sheets per hour. Its 7” full-color touchscreen control panel allows operators to set up jobs easily and to program an unlimited number of jobs into memory. Fully-enclosed fold plates feature dials to select fold plate position and LED displays accurate to 0.1mm. The fold rollers are made of a durable composite material designed to easily grip high-gloss paper, and are housed in a single patented pull-out cassette.

The powerful air suction feed table handles a wide variety of coated or non-coated stock, up to 26.5” in length, and aligns the sheets prior to folding. It also features a suction chamber to control curled or statically charged paper. |

|

Standard features include a modular perforator/scorer which can also be used as a roller bypass, allowing cover stock to be folded and output flat. The belt-driven outfeed stacker is located on the same side as the infeed, allowing operators to easily operate the Atlas from a single position. Double document and jam detection, batch counting, anti-static brushes, skew and micro adjustments complete the user-friendly package.

The Atlas-AS Air-Feed Folder is ideal for those with big folding jobs and limited space.

Atlas-AS Product Spec Sheet

The Atlas-AS Air-Feed Folder is ideal for those with big folding jobs and limited space.

Atlas-AS Product Spec Sheet